This free propeller shaft bearing spacing calculator helps you determine the maximum allowable unsupported length between two bearings on a propeller shaft based on shaft diameter, max engine RPM, gear ratio, shaft weight, and modulus of elasticity. The calculator utilizes the following industry accepted formula endorsed by shaft manufacturers, classification societies, and industry governing bodies:

L = Maximum unsupported length of shaft in feet

D = Shaft diameter in inches

N = Maximum Propeller Shaft Speed in RPM

E = Modulus of elasticity of shaft material, in tension (psi)

W 1 = Weight in pounds per cubic inch of shaft material

Why Propeller Shaft Bearing Spacing is Important

Not only can propeller shafts break or become permanently bent if they are under sized, they can also whip and vibrate excessively if they are not fully supported. Shaft whip and/or shaft vibration can make for an uncomfortable ride for your boat’s passengers and can also lead to premature failure of your boat’s driveline gear. This calculator helps determine the maximum distance between two bearings for a given propeller shaft setup.

Minimum Distance Between Two Propeller Shaft Bearings

As per American Boat and Yacht Council, the minimum amount of distance between two shaft cutless bearings should be at least equal to a measurement 20 times of the shaft’s diameter to help facilitate alignment. For example, the smallest distance you could have between two propeller shaft bearings for a 2″ shaft would be 40″ (3′ 4″). There will be exceptions to the rule, but these are the recommend best practices.

Instructions for Propeller Shaft Bearing Spacing Calculator

Similar to our propeller shaft size calculator, there’s a couple variables in the shaft bearing spacing calculator that the casual user may have trouble locating. Without going into exhausting detail, I’ll simply break these two variables down below and explain where to find the values you need for your particular boat building project.

Modulus of Elasticity

While modulus of elasticity sounds like an incredibly imposing term (and rightfully so), it is a value that is readily available by any reputable shafting manufacturer. It is expressed in pounds per square inch (psi) and is typically around 28,000,000 (that’s million) depending on the alloy in question.

At R.E. Thomas Marine Hardware we use Aqualoy 22 and Aqualoy 22 HS by Western Branch Metals in our custom propeller shafts. You can download their technical information for their shafts including MOE values here (page 8).

For the purposes of this calculator, you can use the following values for AQ17, AQ19, AQ22, and 316.

Aqualoy 17: 28,500,000 psi

Aqualoy 19: 28,000,000 psi

Aqualoy 22: 28,000,000 psi

316 Stainless: 28,000,000 psi

Shaft Alloy Weight

The final variable we need to calculate the maximum allowable space between two propeller shaft bearings is the shaft’s weight in pounds per cubic inch.

Once again, this value is readily accessible by any reputable manufacturer of propeller shafting stock whether you use an AQ alloy, 316 stainless, or bronze. I have included a sample of shaft weights based on information provided by Western Branch Metals for their different grades of marine shafting. You can verify this information yourself on the Western Branch website here (page 8). If you’re using propeller shaft stock from a different manufacturer, be sure to verify the weights for the material you intend to use.

Select Shaft Weights per Cubic In

Aqualoy 17: .284

Aqualoy 19: .284

Aqualoy 22: .286

316 Stainless: .288

Propeller Shaft Strength vs Stiffness

In contrast to our propeller shaft size calculator that measures a propeller shaft’s “strength”, the calculator on this page focuses on the “stiffness” of a propeller shaft. So what’s the difference between shaft strength and shaft stiffness?

Shaft Strength: When we’re talking about the strength of a propeller shaft, we’re talking about the force that needs to be applied before the propeller shaft either breaks or permanently deforms (yield strength).

Shaft Stiffness: When we’re talking about the stiffness of a propeller shaft, we’re talking about how the shaft bends to resist the external force that is being exerted on it while still being able to return to its original shape or form. If the propeller shaft is not properly supported, the “elasticity” in the shaft can cause it to whip often times resulting in excessive vibration and noise. Over time this vibration can lead to premature failure of the driveline system including the shaft, transmission, engine, propeller, shaft seal, and bearings.

The 40 times the Diameter Rule of Thumb

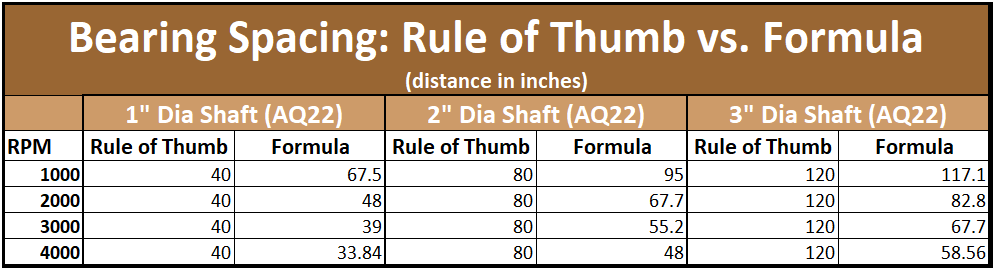

While making this calculator, we couldn’t avoid thinking about the “rule of thumb” that the maximum allowable distance between two propeller shaft bearings should be no more than a measurement equal to 40 times the diameter of a propeller shaft. To see how this compares to the actual formula, we’ve put together this table. The table looks at three different shaft diameters of Aqualoy 22 at different shaft RPMs. As expected, the higher the RPM goes, the lower the formula’s recommended max distance goes. We find that the rule of thumb has some merit for casual conversations, but we strongly recommend any shaft bearing design to be approved by a naval architect or appropriately experienced marine engineer.

Disclaimer: The information provided on this page (including the calculator) is intended for general informational purposes. For more specific information shaft bearing specifications and recommendations, we strongly advise you to consult with an experienced naval architect familiar with your particular style of boat.