What’s the difference between boats with wet keels vs dry keels? How do you know if your boat has a “wet keel”? Which is better a “wet keel” or a “dry keel”?

If you are relatively new to “Downeast” style boats, you may have had similar questions to the ones listed above. Even the most seasoned blue water sailors and “yachtsmen” can be overwhelmed when they start plying into the design characteristics of Downeast style boats.

RE Thomas Marine Hardware specializes in heavy duty marine hardware for Downeast style boats. In fact, we are proud to be an OEM supplier of propeller shafts, shaft bearings, and shaft seals to many of the world’s finest boat builders.

While we deal directly with boat builders and boat yards, we also spend a lot of time working directly with boat owners who are not as knowledgeable when it comes to the design of their specific boat.

When a customer calls with an issue regarding their boat’s running gear system, one of the first questions we ask them is whether their boat has a “wet keel” or a “dry keel”. Often, this question is met with a long pause followed by a hesitant “I’m not sure”, or “I don’t know what you mean”.

The intent of this article is to explain the difference between wet keels vs dry keels and help make you a more knowledgeable boater. The more knowledgeable you are about your boat’s running gear system, the better prepared you’ll be when it comes to maintenance issues and repairs.

The Evolution of the Downeast Style Lobster Boat:

Before we go any further in explaining the difference between wet keels vs dry keels, we must first look at the unique hull design of a modern Downeast style boat.

Downeast boats are defined by their high rising bows that gradually taper towards the back of the boat where the deck rail is lower to the water. More importantly, they feature a full keel/skeg that runs the full length of the boat’s bottom like a long fin.

The full keel/skeg is important because it helps keep the boat stable in rough water, and it helps protect the propeller and rudder from running aground. It’s easy to see why these features were important to fishermen if you’ve seen pictures of Maine’s rocky coastline.

The Transition to Fiberglass:

Until about 35-40 years ago, most Downeast style boats were made of wood by highly skilled boat builders. As modern boat building technologies improved, Downeast boat builders began using fiberglass in the construction of their boats.

Molds were taken from the hulls of the best performing wooden boats which where then used in the production of identically shaped fiberglass hulls. The transition to fiberglass hulls was very quick. While many preferred the ride quality and beauty of traditional wooden boats, the cost savings and speed at which a fiberglass boat could be built were hard to ignore.

However, the transition to fiberglass created a new problem for Downeast boat builders. The keel and skeg of traditional wooden lobster boats were constructed of solid wood. The propeller shaft ran through a long hollowed out timber that entered the engine compartment (hence the term shaft log). The process of molding these hulls out of fiberglass created a huge empty void space in the keel/skeg area.

The challenge for boat builders was finding a way to support the propeller shaft as it ran through the empty keel/skeg of these new fiberglass boats. After years of trail and error, two basic concepts were adopted as best practices. One method was the so called “wet keel” system, and the other was the “dry keel” system.

Boats with a Wet Keel:

What is a wet keel? As the name suggests, boats classified as having a wet keel are designed to carry water in the keel of the boat.

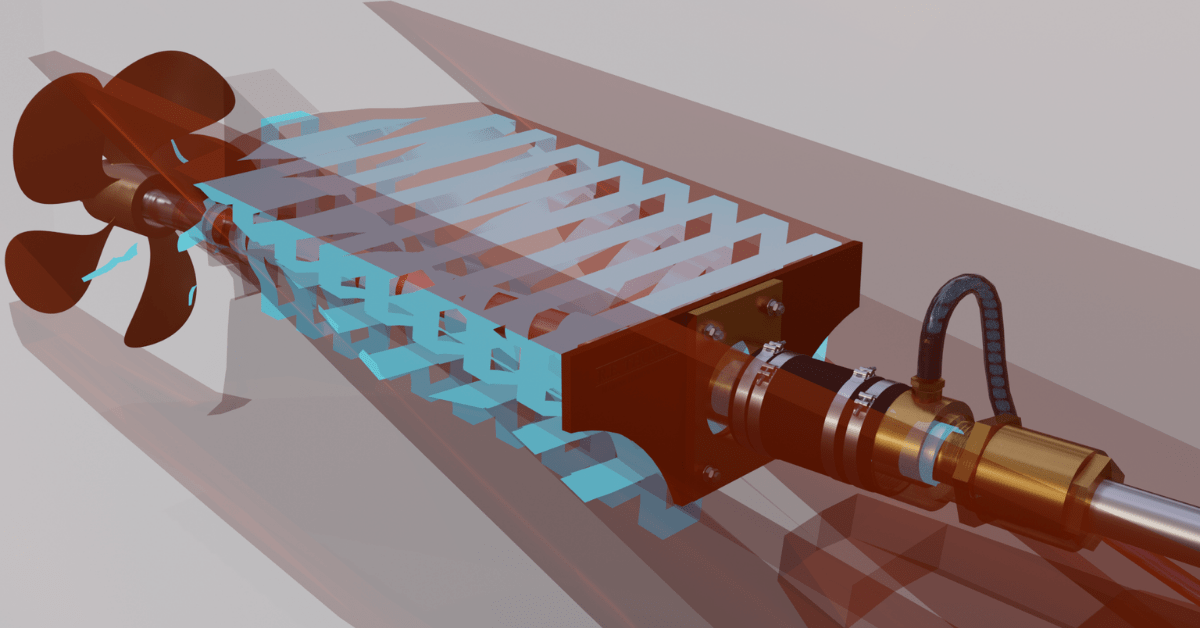

In the simplest terms, a wet keel is made by building a tank out of the void space in the boat’s keel/skeg area. This usually done by fiberglassing a ceiling and forward bulkhead into the keel where water can be contained.

The propeller shaft enters the wet keel through a bronze stern bearing housing at the back of the boat and passes through another shaft bearing and shaft seal as it enters the engine compartment. This shaft seal is usually fed with water to help keep the shaft bearings lubricated and cool.

There are several advantages of a wet keel vs a dry keel.

First, many boat owners contend that having the extra weight (or less buoyancy) in the keel of the boat helps the boat ride better in the water.

Second, water in a wet keel helps lubricate the rubber bearings that support the weight of the shaft as it runs through the boat. Many marine mechanics will also tell you its easier to replace Cutless© shaft bearings in boats with wet keels.

Finally, the double bottom that is created in a wet keel system offers added protection in case the hull is holed (penetrated). This can be a very important feature along the rocky coast of Maine where lobster boats operate very close to rocky ledges. If you remember back to the grounding of the Exxon Valdez, double hulls were one of the resulting regulations as part of OPA-90.

Boats with a Dry Keel:

What is a dry keel? Once again, there are connotations in the name. Boat’s classified as having a dry keel are designed to not carry water in their keel/skeg.

Instead, a fiberglass shaft tube (sometimes called a stern tube) is molded into the hull of the boat from the end of the skeg all the way forward into the engine compartment. The shaft is run through this shaft tube and is supported (once again) by water lubricated shaft bearings (Duramax Johnson Cutless© bearings).

Water is kept out of the engine compartment by connecting a propeller shaft seal to the end of the shaft tube. On higher horsepower boats, this shaft seal is fed by a water hose to help keep the shaft bearings cool.

There are advantages to a dry keel vs a wet keel.

All other things being equal, a boat with a dry keel can theoretically carry more weight than a boat with a wet keel. The reduced weight carried in the keel can also lead to more speed and higher fuel efficiencies.

Second, it is slightly less expensive to build a dry keel boat over a wet keel boat due to the heavy (expensive) bronze bearing housings needed in a boat designed with a wet keel.

Outside Stuffing Boxes:

Although rare, a second style of “dry keel” boat uses what is known as an outside stuffing box. In this design, water is prevented from entering the hull of the boat. This sounds ideal, but it creates several problems.

Keeping water outside the hull prevents the shaft bearings from the cooling and lubrication they need to function properly.

Second, stuffing boxes can require a lot of maintenance and adjustment. Having the stuffing box on the outside of the boat (underwater) makes them difficult to work on.

Finally, its better to have a dedicated shaft bearing support the shaft than a stuffing box. This helps ensure proper distribution of thrust forces generated by the boat’s propeller. Relying on the stuffing box to support the shaft and create a watertight seal is a recipe for failure.

Which Is Better:

When it comes to wet keels vs dry keels, it usually comes down to personal preferences. In fact, most Maine boat builders can finish their boats as either dry keel boats or wet keel boats. Their main concern is building you a boat that you’ll be most comfortable in. Both designs have proven themselves as viable options over the last few decades.

We hope you found this article helpful! Please feel free to contact us with any questions you may have regarding propeller shafts and their components.

Thanks for the information; it have me a better understanding