Question: I’m repowering my boat and my mechanic suggested I use a tapered coupling instead of a traditional split coupling. What’s the difference between the two, and why is an RE Thomas tapered coupling better?

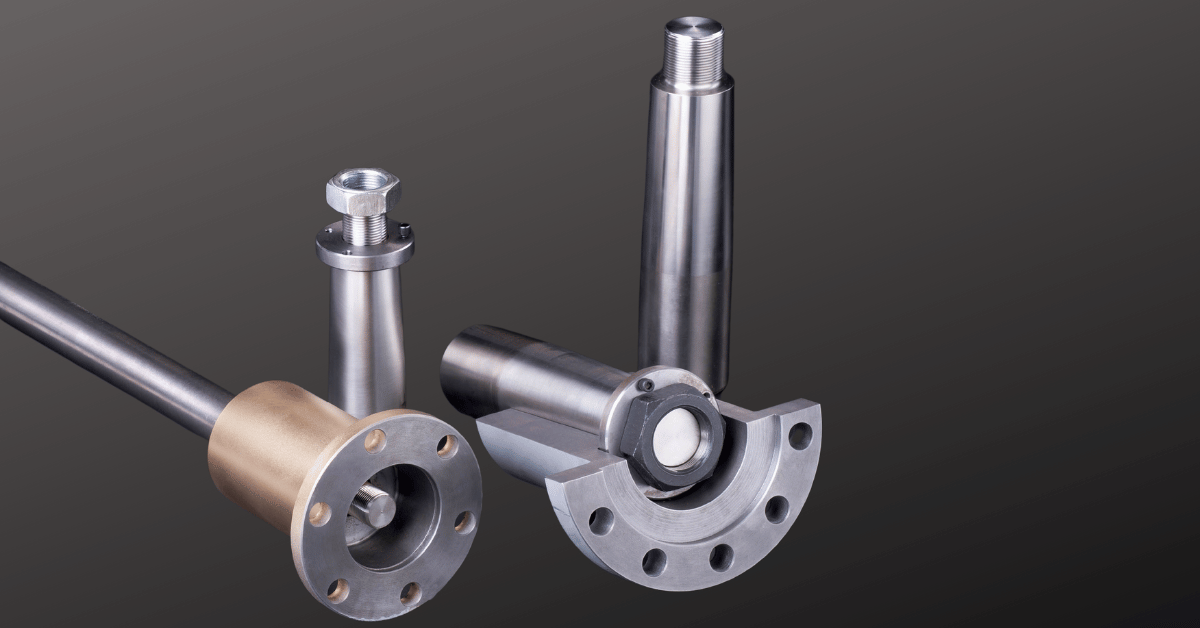

When it comes to inboard powered boats, the propeller shaft coupling plays a crucial role in ensuring the efficient transfer of power from the engine to the propeller. There are various types of propeller shaft couplings available in the market, but in this article, we will focus on the advantages of a tapered coupling over the more commonly used split propeller shaft couplings.

Advantages of Tapered Couplings

- Superior Strength and Holding Power

- Better Alignment

- Reduced Installation Error

- Reduced Vibration

- Improved Fuel Efficiency

- Reduced Maintenance Costs

What’s the Difference?

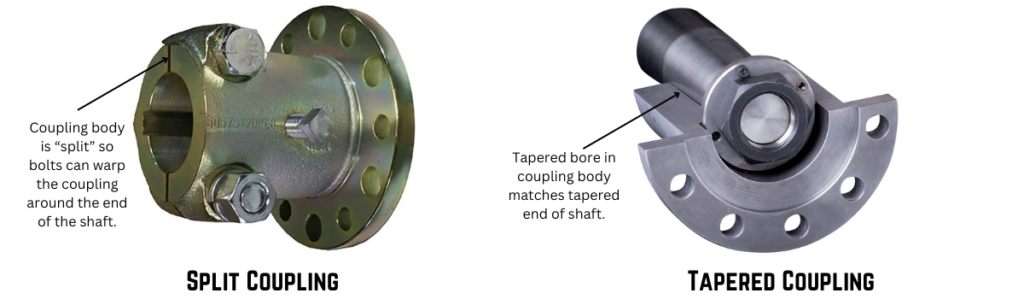

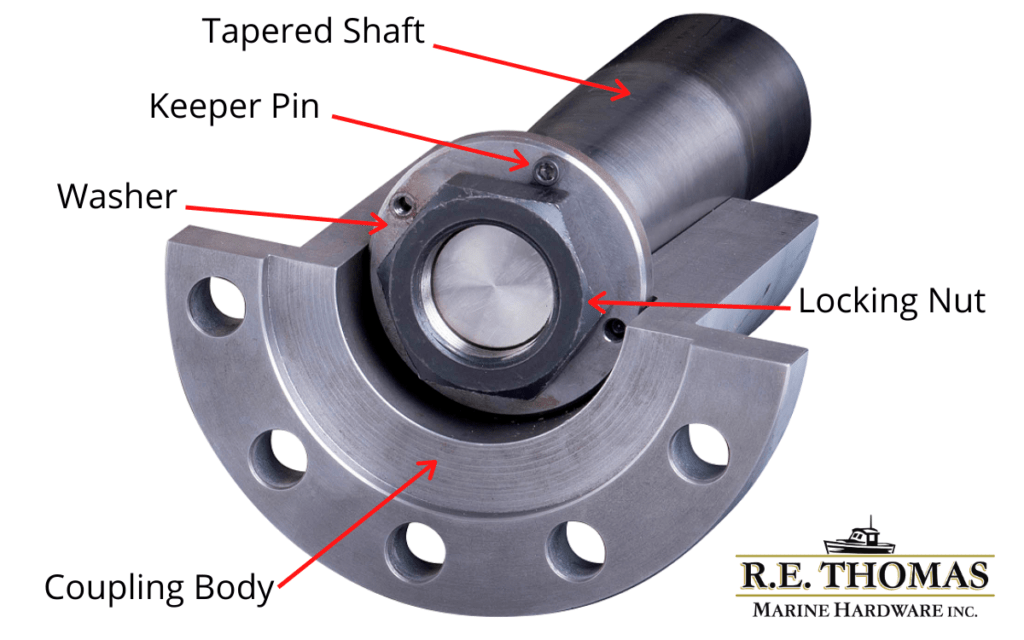

A propeller shaft coupling is essentially a device that connects the propeller shaft to the engine or gearbox, allowing the transfer of torque. Split propeller shaft couplings consist of two separate halves that are bolted together around the propeller shaft. On the other hand, tapered propeller shaft couplings have a conical shape, which allows for a tight and secure fit onto the shaft.

Superior Strength and Holding Power

One of the major advantages of tapered propeller shaft couplings is their superior strength and durability. The tapered design provides a significantly larger contact area between the coupling and the shaft, resulting in a higher load-bearing capacity. This means that a tapered coupling can handle higher torque without the risk of slipping or failure, making it more reliable and robust than a split coupling.

Better Alignment

The tight fit achieved by tapered couplings also enhances the overall efficiency of the propulsion system. The secure connection between the shaft and the coupling ensures that there is minimal power loss during transmission. This means that more power generated by the engine can be effectively transferred to the propeller, resulting in improved performance and fuel efficiency. In contrast, split couplings usually suffer from misalignment due to over torqueing or under torqueing the set bolts.

Even if a split coupling is installed perfectly, and faced in a lathe (as recommended by ABYC standards), there is no guarantee that the mechanic is going to re-install the coupling the exact same way when they get the assembly to the boat.

Reduced Vibration

Another key advantage of tapered propeller shaft couplings is their ability to dampen vibrations and reduce noise. The tapered shape helps absorb and dissipate vibrations generated during engine operation, resulting in a smoother and quieter performance. This is particularly important in marine applications where excessive noise and vibrations can impact the comfort of passengers and crew members, as well as the integrity of onboard equipment.

Furthermore, tapered propeller shaft couplings offer easy installation and maintenance. The conical design allows for a simple and straightforward assembly process, requiring fewer components and reducing the chances of errors. In contrast, split couplings usually need to be “hammered” on to the end of a propeller shaft causing even more alignment issues.

Reduced Maintenance Costs

The secure fit also means that the coupling does not require frequent inspection or tightening, saving valuable time and effort. In contrast, split couplings often need regular maintenance to ensure that the halves remain properly aligned and bolted, which can be time-consuming and labor-intensive. Tapered couplings are also removed with less effort (and less potential damage) than spilt couplings.

In terms of cost-effectiveness, tapered propeller shaft couplings also come out on top. While the initial purchase cost may be slightly higher than that of split couplings, the long-term economic benefits outweigh the difference. The durability and reliability of tapered couplings result in reduced downtime and maintenance costs, as well as improved fuel efficiency. Additionally, the minimal power loss due to the tight fit translates into savings in fuel consumption, making tapered couplings a cost-effective choice in the long run.

Conclusion

In conclusion, tapered propeller shaft couplings offer a range of advantages over split propeller shaft couplings. Their superior strength, durability, efficiency, vibration dampening capabilities, and ease of installation and maintenance make them a preferred choice for marine propulsion systems. While there are specific applications where split couplings may be suitable, it is clear that tapered couplings provide a more reliable, efficient, and cost-effective solution for the majority of marine propulsion needs.

If you’re building or repowering a boat, give RE Thomas Marine Hardware a call at (207) 422-6532 for a free quote on a tapered shaft and coupling package. We’re a proud OEM supplier of tapered AQ-22 propeller shafts and tapered couplings to many of the world’s finest boat builders.