Does your boat have a leaking rudder port? Leaking rudder ports, or rudder stuffing boxes as they are sometimes called, are a common problem on inboard powered boats. In fact, leaking rudder ports are so common that most people think rudder ports are supposed to leak.

The Problem with Bronze Rudder Ports:

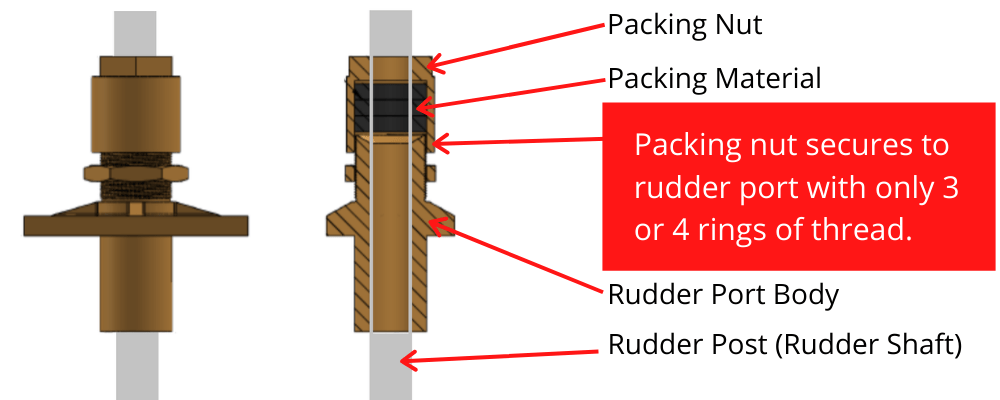

The problem with traditional rudder ports and rudder stuffing boxes lies in their design. Most rudder ports are nothing more than traditional bronze stuffing boxes mounted in a vertical position over the boat’s rudder post. They use a simple packing nut to compress packing material around the shaft. Once the packing nut is adjusted, the locking nut is tightened to prevent the packing nut from coming loose.

While this seems logical, it creates several issues that compromise the integrity of your boat’s entire rudder steering system.

Trying to Do Two Things at Once:

Rudder posts (rudder shafts) create different forces compared to propeller shafts. In addition to torque, rudder ports must withstand the side to side force (sway) created by the rudder as it shifts from side to side.

This side to side force ends up being supported by the packing nut because the packing nut is the primary support structure for the packing material. Refer to the diagram below.

In addition to trying to create a watertight seal, the packing nut is bearing the full turning force of the rudder. The constant bending and jarring inevitably leads to more leaking around the rudder shaft seal. It can also cause the threads to strip or the body of the rudder port to crack.

Hanging on By a Thread:

Because the packing nut is threaded into the body of the rudder port, your rudder shaft does not have a solid support structure. Your boat’s steering system is literally dependent on the thread engagement between the packing nut and rudder port body. Even in the best rudder ports, this thread engagement can only be expected to run 3 or 4 “rings”.

Imagine your boat making a turn at full speed and the resulting force impacting the threads holding your packing nut on. It’s no wonder why so many rudder ports leak and require constant adjustment.

Bigger Engines Same Rudder System:

Another factor causing a leaking rudder port is the fact that many older boats get upgraded with more powerful engines. This is especially true with commercial fishing boats were government incentives for more fuel-efficient engines are available.

Boat owners put a lot of money into upgrading their boat’s engine and propeller shaft, but they do nothing with their rudder system. Rudder shafts originally intended for a 250-horsepower engine just cannot keep up when the engine output is doubled.

The first Innovation in Rudder Port Design

The Wedding Band Packing Nut System:

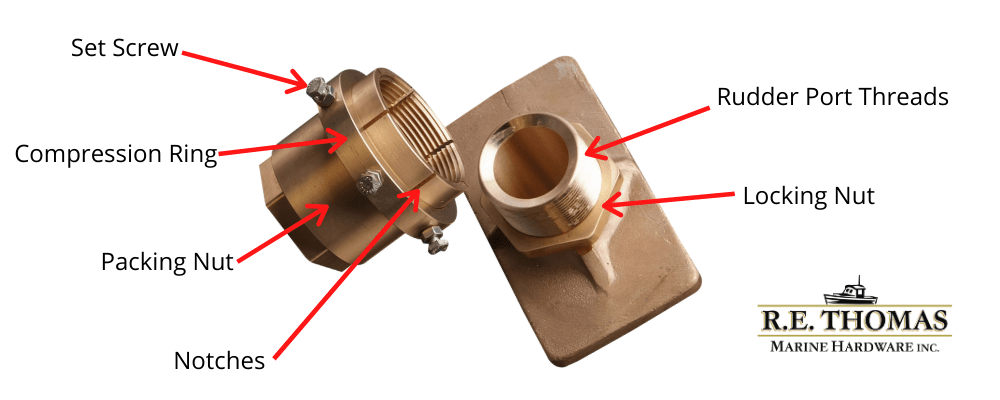

To help improve thread engagement with the packing nut, RE Thomas created the “Wedding Band” system. With the wedding band, the packing nut is notched every 60° of circumference and fitted with a compression ring. Once the packing nut is in place, the set screws on the compression ring are tightened forcing deeper thread engagement between the packing nut and rudder port body.

While not perfect, the wedding band helps prevent the packing nut from backing off and coming loose. However, it does not address the problem of the packing nut bearing all the forces from the rudder post. In order to properly support the forces, the traditional bronze rudder port would need to be tinkered with even more.

The Best Solution

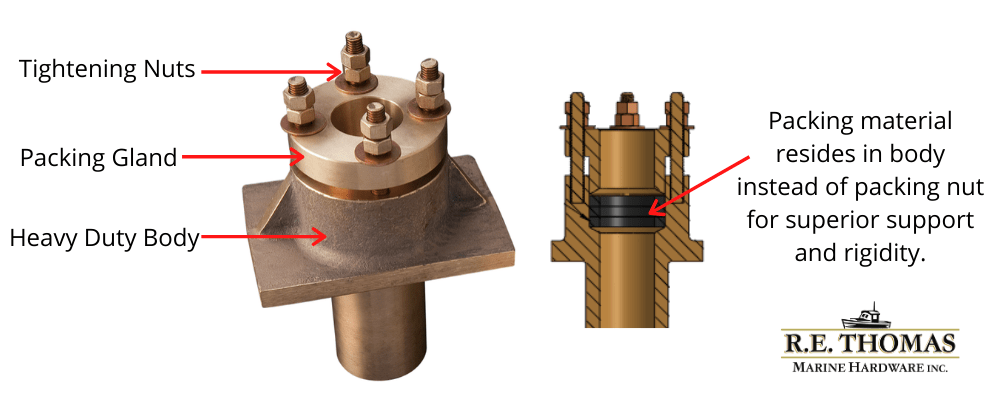

The Heavy-Duty Gland Style Rudder Port:

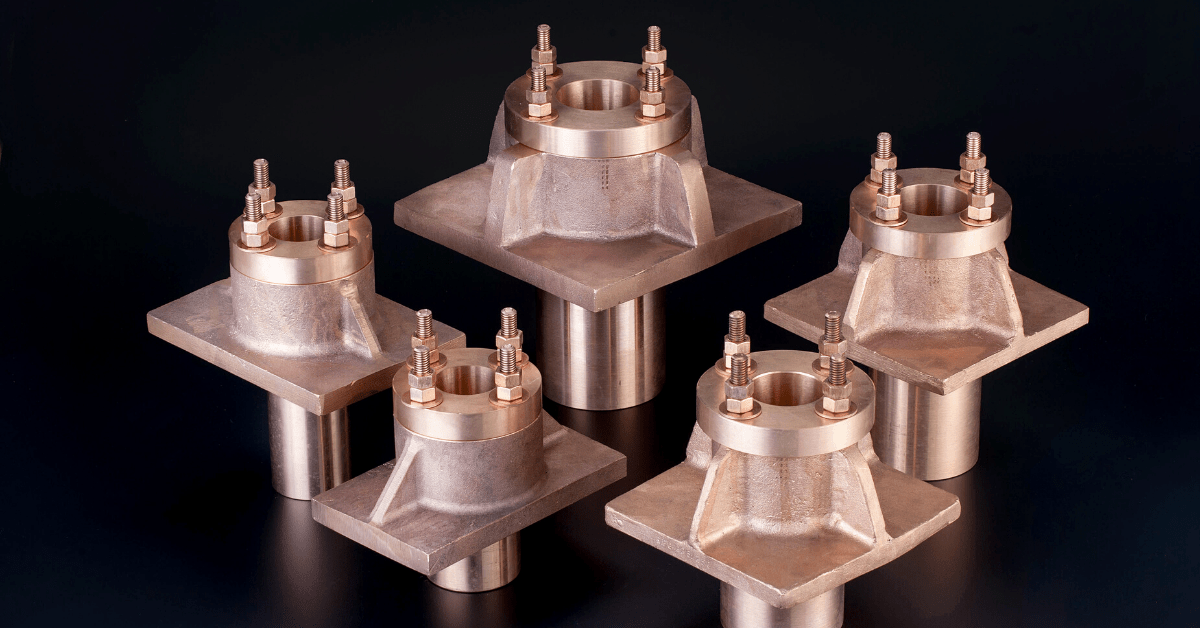

To further improve the performance of traditional bronze rudder ports, RE Thomas began experimenting with a gland style packing system. In this system, the packing material is seated in the actual body of the rudder port instead of the packing nut.

This allows for the casting of a much larger housing to absorb the lateral and axial movement of the rudder post. Furthermore, the packing material is no longer dependent on a single packing nut to hold its compression against the shaft. Instead, 4 studs are threaded into the body to pull the packing gland down to compress the packing material.

The response to our gland style rudder ports was so strong that they were quickly adopted as OEM parts by many of the world’s finest boat builders. Rudder systems could now be installed safely and with less water leaking out into the boat.

Order a New Rudder Port:

If you are interested in upgrading your boat’s leaking rudder port to a gland style system now is the perfect time! You can order online or give us a call at 207-422-6532.

I met Mr Thomas back when he developed the wedding band for his stuffing box , he told me that his rudder boxes were machined to much closer tolerances so the rudder shaft wasn’t relying on the packing for total support . I had a leaky rudder box on every boat I ever had , 6 fishing vessels out of Chatham over the years , after installing the rudder box and wedding band I never had any more leaks ,The best under water equipment in the industry , and I know that many fishermen and boat builders use your gear today because I let anybody that would listen know to buy the best underwater gear from R E Thomas , PS he was a gem of a guy , RIP